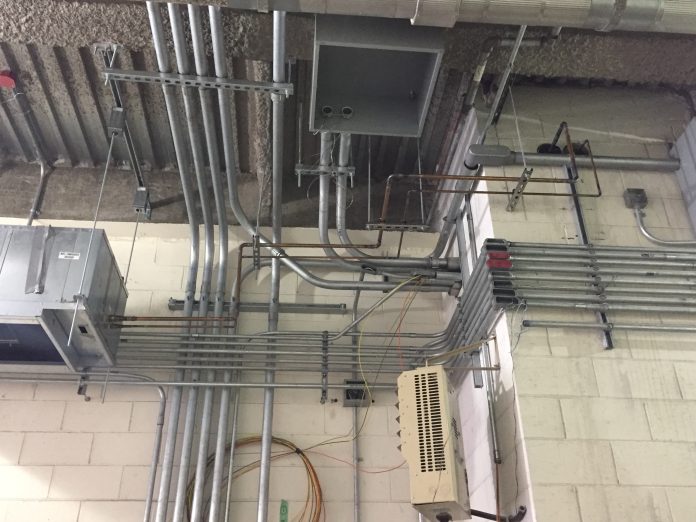

Concealed conduit wiring

The conduits are all installed into the wall with this method of wiring. The conduit should be covered with 1/4 inch of plaster in underwater work. Do you conceal conduit wires in walls? You will never splice wires together and conceal them without a junction box within a wall. It’s a fire hazard. Using proper wiring rules for in-wall wiring and installing a junction box accessible to the connected wires helps you in this process.

Materials required for concealed conduit wiring

Wire for concealed conduits is made of the following materials:

- Boards made from wood

- Taps for installation

- Box for junction

- Box for the ceiling rose

- With lamp holder

- Cable in PVC

- Cable

- Switches

- Connectors

- Fasteners

- Tubes Ties

- Tube Elbow

- Fuse Kit

- The Bushing

How to install concealed conduit wiring?

Step 1: Installing electrical conduit in the slab.

- FR PVC conduits of two millimeters thick and 25 millimeters in size should be used for the slab conduits of a house. There should be a slab conduit positioned between the top and bottom reinforcements. Please ensure the concrete thickness covers the PVC conduits when using singly reinforced slabs.

- Deep junction boxes should only be used in slabs. Ensure the PVC conduits are properly bonded with Binding wires.

- Consider different color coding for data conduits (LAN wire, telephone wire, etc.) and electrical conduits.

- Utilize gray PVC pipes for data and black PVC pipes for electrical wiring. The solvent is used to join the accessories.

- Wall drops must be adequately checked for wall/beam face. Ensure concrete is thick enough to cover the beam/wall face.

- All wiring shall be verified following the services drawing, which includes the locations of switchboards and the number of points at each location.

- Extra care should be taken during concrete pouring to avoid damage to the slab.

- GI wire passing must be carried out immediately after slab & beam de-shuttering. (Any choke-ups must be documented, and alternate routing must be shown in shop drawings and documented for future reference).

- Before slab casting, all necessary sleeves must be incorporated into beams and columns according to electrical and air-conditioning codes.

- Pull boxes must be provided at appropriate locations.

- As per electrical drawings, pull and junction boxes should not be clustered in one place and should be arranged so as not to be easily seen from heavy traffic areas.

Step 2: Laying electrical conduits in walls.

- Concealed conduit work shall be carried out after constructing masonry walls before plastering.

- Chasing work should be performed after curing brickwork (after at least seven days).

- Wall cutting should only be done with wall cutters to avoid damaging the walls.

- For proper routing and wiring in the future, the conduits shall be fitted with approved clips.

- The chiseled surface should be filled with cement mortar and covered with chick mesh after the conduits, boxes, and accessories have been installed.

- The first step in conducting wall work is to mark the wall’s level (usually box level), knowing its height above the floor (Finished Floor Level).

- Following the number of conduits, the width of chasings must be limited.

- For conduit recess to be at least 10mm from the masonry wall, the chasing depth must be 10mm deep.

- All horizontal conduit runs should be straight from the box to the conduit recess. Vertical cable runs from weak points to switch boxes should be straight. Wall conduits should never be taken haphazardly.

- No elbows or bends should be used. If the direction of the pipe needs to be changed, use a spring to bend the pipe.

- Power conduits should never be placed near any communication lines.

- All conduits above false ceilings must be supported or suspended correctly. Under no circumstances shall conduits be supported on a false ceiling grid. In cases of false ceiling work, all vertical runs with open ends must be sealed at the top when masonry civil work is underway.

Step 3: Install the switchboard back boxes

- As per the schedule, all concealed switchboards shall be leveled correctly (Height, distance from Finished Floor (FFL) should be following the architect’s recommendation).

- The gap between concealed switchboards shall be uniform & maintain the same for every installation.

- A switchboard shall be a ready-made modular metal box of approved make and drawing.

- The concealed box must be recessed 3 mm into the plastered surface.

- Box fixing and wall conducting should be completed before plastering. These boxes should be filled with thermocol while plastering is taking place.

Step 4: Install the distribution boards.

- DBs should be concealed before plastering begins.

- A DB box shall be positioned in a properly aligned and leveled recess in the brickwork.

- The DB shall be ready-made as per design (fixing the number of conduits pipe entering DBS).

- All PVC pipes must enter DB only through the given entry holes.

Pros of a concealed conduit wiring system

Read more:Top Best Methods About Fixing If Fan Is Making Noise With Description

- The product has a long life expectancy.

- This is the safest wiring system available.

- It is easy to maintain.

- If metallic pipes are earthed and appropriately grounded, there is no risk of electrical shock.

- The fire does not change.

- No damage to cable installations is possible.

- Alternatives are possible.

- Several customizations can be done quickly according to our future needs.

- This is a waterproof wiring system.

- The system is durable and highly popular.

- There will be no combustion support.

- Corrosion is not an issue for PVC conduct, and there is no fire risk.

- The conductor is moisture-proof.

- This wiring seems more attractive.

- The aesthetics are appealing.

Cons of concealed conduit wiring system

- There is a high cost of this system compared to other systems.

- An earthling conductor is required when PVC conduct is used.

- It is challenging to find any defects in the wiring.

- A conduit needs to be added because it is cumbersome

- Conductors made of PVC are not suitable for temperatures below -5°C or above 60°C.

- Alternation is hard.

- Besides, wiring installation is more complex than other methods.

- Changing the location of appliances or switches is challenging.

- Fault-finding is complicated.

- It’s difficult to add/manage additional connections in the future.

What are the benefits of hidden wiring?

Concealed electrical wiring systems have advantages.

Of the various wiring systems discussed above, it is among the safest. It has a pleasing aesthetic quality. Fire danger or mechanical deterioration are nonexistent. Cable insulation deterioration is not a concern.